Written by

Temple Grandin, Ph.D.

Assistant Professor

Colorado State University

2nd Edition

For the best results in animal handling, plant management must make proper handling and stunning a high priority. Top management must play an active role. Plants with the best handling and stunning practices have management who closely monitor stunning and handling practices. This manual provides employees and managers with information which will help them improve both handling and stunning. Employees handling hundreds of animals day after day sometimes need reminders from management that animals must always be handled carefully.

Healthy animals, properly handled, keep the meat industry running safely, efficiently and profitably. This handbook is designed to help ensure that proper handling guidelines and recommended practices are widely understood. It is designed to be used in conjunction with the publication on Good Management Practices for Animal Handling and Stunning which contains the objective scoring system that managers can use to maintain good handling and stunning practices.

New concrete floors for cattle should have an 8-inch diamond or square pattern with 1 ½ inch x 1 ½ inch V grooves. For hogs and sheep, stamp the pattern of 1 ½ inch (3.8 cm) raised expanded metal into the wet concrete. A rough broom finish will become worn smooth. Floors should be grooved. It is also essential to use the right concrete mix for maximum resistance to wear.

Gates, fences and chutes should have smooth surfaces to prevent bruises. Sharp edges with a small diameter, such as angle irons, exposed pipe ends and channels, will cause bruises. Round pipe posts with a diameter larger than 3 inches (8 cm) are less likely to bruise. Vertical slide gates in chutes should be counter-weighted to prevent back bruises. The bottom of these gates should be padded with cut tires or conveyor belting. The gate track should be recessed into the chute wall to eliminate a sharp edge that will bruise. In pork plants, the bottom 18 in.(46 cm) to 24 in. (61 cm) of a vertical slide gate can be cut off and replaced with a curtain made from conveyor belting. The pigs will not attempt to go through the curtain. This change will prevent back injuries if the gate is closed on a pig.

This bad bruise point could cause damage to both hide and meat

Pressing up against a smooth flat surface such as a concrete chute fence will not cause bruises. However, a protruding bolt or piece of metal will damage hides and bruise the meat. Bruise points can be detected by tufts of hair or a shiny surface. Contrary to popular belief, livestock can be bruised moments before slaughter and stunned cattle can be bruised until they are bled. The entrance to the restrainer should be inspected often for broken parts with sharp edges.

Surveys show that groups of horned cattle will have twice as many bruises as polled (hornless) cattle. A few horned animals can do a lot of damage and tipping horns does not reduce bruises. Cutting off the horn tips will not reduce bruising.

Improving Animal Movement – Calm animals are easier to handle and move than excited animals. Animals can become agitated very quickly but 20 to 30 minutes is required for them to calm back down. To keep animals calm, handlers should be quiet. Yelling and arm waving excites and agitates animals. Cattle, hogs and sheep have wide-angle vision and they can see behind themselves without turning their heads. This explains why they will often balk at shadows or puddles of water on the ground. Balking slows production and can be prevented. Drains should be located outside of the areas where animals walk. A drain or a metal plate running across an alley will cause balking. Flapping objects such as a coat hung over a fence will also make livestock balk. When wetting hogs in the chute, be sure not to spray the animal’s face with water because they will back up.

Animals tend to move from a darker area to a more brightly lighted area. Lamps can be used to attract animals into chutes. The light should illuminate the chute up ahead and it should never glare directly into the eyes of approaching animals. Another approach is illuminating the entire chute area. This approach eliminates patches of light and dark which may confuse animals.

Solid sides which prevent the animals from seeing outside the fence should be installed on the chutes which lead to the stunner and the crowd pen which leads up to the chute. Solid sides in these areas help prevent animals from becoming agitated when they see activity outside the fence – such as people. Cattle tend to be calmer in a chute with solid sides. The crowd gate on the crowd pen should also be solid to prevent animals from attempting to turn back, towards the stockyard pens they just left.

It is important to reduce noise in the stunning area. Animals are more sensitive to high-pitched noise than people. Studies have shown that the sound of people yelling and whistling is stressful to cattle. Animals will be calmer and easier to handle if noise levels are reduced. Install mufflers on air valve exhausts or put them outside. Rubber stops on gates can be used to stop clanging. Braking devices on the shackle return improve safety and reduce noise. Use large diameter plumbing and replace pumps with quieter ones. Some brands of pumps are quieter than others. Rubber hose connection between the power unit and metal plumbing will help prevent power unit noise from being transmitted throughout the facility. Any new equipment that is installed in animal breeding or stunning areas should be engineered for quietness.

Improving Meat Quality and Animal Welfare – All livestock must have access to clean drinking water. During hot weather (over 70 degrees Fahrenheit), hogs should be sprinkled with water in the stockyard pens. For maximum cooling effect, the sprinklers should have a coarse enough spray to wet the animals. Sprinklers that make a fine mist should not be used because they tend to increase humidity rather than cool the hogs. Sprinkler waster should flow intermittently to keep hogs wet at all times. Keeping hogs cool is very important because a hot hog will have PSE (pale, soft, exudative, stressed pork). Hogs become over heated easily because they are covered by a layer of fat and they do not sweat. All hog plants should have a heated staging area prior to the stunning chute where hogs can be showered prior to stunning during cold weather.

Using Prods and Persuaders Properly – Electric prods should be used sparingly to move livestock. An electric prod should not be a person’s primary driving tool. It should only be picked up and used on a stubborn animal and then put back down. After the distractions that cause balking have been removed from a facility, it will be much easier to greatly reduce or possibly eliminate electric prod use. In many plants, electric prods have been eliminated in the yards and in the crowd pen that leads up to the single file chutes. Easily attainable electric prod scores are 5% or less of the cattle and 15% or less of the pigs. In systems where pigs are herded in groups, electric prods can be eliminated. Electric prods must never be wired directly to house current. A transformer must be used. Hogs require lower voltages than cattle. A doorbell transformer works well for hogs. Low prod voltages will help reduce both PSE and blood spots in the meat. Fifty volts is the maximum voltage for prods hooked to an overhead wire. Battery-operated prods are best from a livestock handling standpoint because they provide a localized directional stimulus between two prongs. Progressive managers have removed wired in prods and use only battery-operated prods.

The use of electric prods can be greatly reduced by using other driving aids such as plastic streamers or strips cut from garbage bags attached to a stick. Cattle can be easily turned and moved in the crowd pen by shaking the streamers near their heads. For moving pigs, a large flag on a short handle or rattle paddle work well. The flags are made from lightweight plasticized tarp material and can vary in size from 20 in. x 20 in. to 30 in. x 30 in.(50 cm x 50 cm to 76 cm x 76 cm) Rattles work well for moving sheep.

Truck drivers should be careful with livestock. Rushing livestock during unloading is a major cause of bruises. Serious loin bruises are often caused by two cattle wedged in a truck door. Management should closely supervise truck unloading. Electric prods are seldom needed for unloading trucks.

Providing Adequate Pen Space – Stockyards at packing plants should have sufficient capacity so that animals can be promptly unloaded from trucks. Heat builds up rapidly in a stationary vehicle. To reduce PSE, hogs should be rested two to four hours prior to stunning. In large plants, pens should be designed to hold one or two truckloads. A few smaller pens will also be required for small lots. Pen space allocations may vary depending upon weather conditions, animal sizes and varying holding times. As a guideline, 20 square feet (1.87 m) should be allotted for each 1,200-pound (545 kg) steer or cow and six square feet per hog. These stocking rates will provide adequate room for “working space” when animals are moved out of the pen. If the animals are stocked in the pen more tightly, it will be more difficult for the handler to empty the pen. The recommended stocking rates provide adequate space for all animals to lie down.

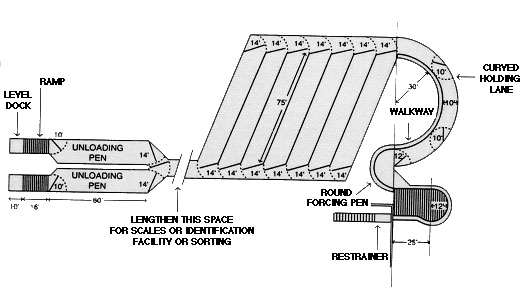

Recommended Handling Facility Layout – This diagram illustrates a modern cattle stockyard and chute system. All the animal movement is one-way and there is no cross traffic. Each long narrow pen holds one truckload. The animals enter through one end and leave through the other. The round crowd pen and curved chute facilitate movement of cattle to the stunner.

Facility Layout – Modern cattle facility with many good features. The unloading ramps have a 10-foot (3 m) level dock for the animals to walk on before they go down the ramps. Each unloading pen can hold a full truck load. Unloading pens are recommended for both hog and cattle facilities to facilitate prompt unloading. Long, narrow diagonal pens eliminate sharp corners and provide one-way traffic flow. The round crowd pan and curved single file chute take advantage of the natural tendency of cattle to circle.

A curved chute is more efficient for cattle because it takes advantage of their natural circling behavior. It also prevents them from seeing the other end while they are standing in the crowd pen. A curved chute should be laid out correctly. Too sharp a bend at the junction between the single file chute and the crowd pen will create the appearance of a dead end. All species of livestock will balk if a chute looks like a dead end.

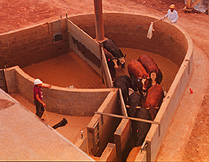

Round crowd pen with correct number of cattle

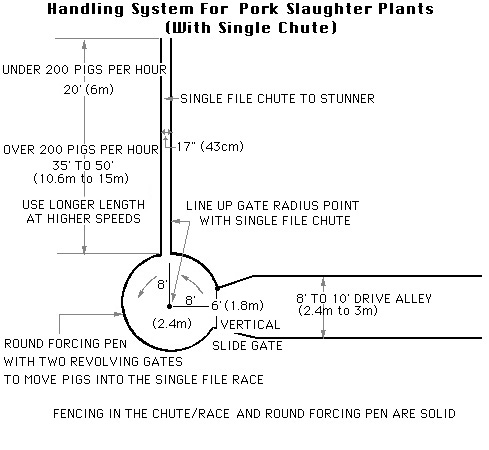

As a guideline, the recommended radii (length of crowd gate) are: Cattle, 12 feet; (3.5 m) hogs, 8 feet (2.5 m) and sheep, 8 feet (2.5 m). The basic layout principles are similar for all species, but there is one important difference. Cattle and sheep crowd pens should have a funnel entrance and hog crowd pens must have an abrupt entrance. Hogs will jam in a funnel. A crowd pan should never be installed on a ramp because animals will pile up in the crowd pen. If ramps have to be used, the sloped portion should be in the single file chutes. In hog facilities, level stockyards and chute systems with no ramp are most efficient.

In CO2 stunning systems, single file chutes can be eliminated. This will provide many advantages for handling pigs. Single file chutes work well for cattle and sheep because walking in single file is a natural behavior for these animals. Pigs are easier to handle in small groups which can be moved from a group pen into a gondola elevator in the CO2 machine.

Unloading Animals Properly – For all species, a plant should have sufficient unloading ramp capacity so trucks can be unloaded promptly. In large plants, at least two and preferably three ramps are required. Unloading ramps should have a level dock before the ramps go down so that animals have a level surface to walk on when they exit the truck. The slope of the ramp should not exceed 20 degrees. On concrete ramps, stairsteps are recommended because they provide better traction than cleats or grooves when ramps become dirty.

Well-designed unloading ramp

For cattle, the recommended stair step dimensions are 3 ½ inch (10 cm) rise and a 12-inch (30 cm) long tread. If space permits, an 18-inch (45 cm) long tread will create a more gradual ramp. For hogs, a 2 ½ inch (6.5 cm) rise and a 10-inch (26 cm) tread works well. On adjustable ramps, cleats with eight inches (20 cm) of space between them are recommended. All flooring and ramp surfaces should be non-slip. Many animals are injured on slippery unloading ramps.

Recommended Trucking Practices – Trailers should be kept in good repair and have nonslip floors. Careful driving will also help prevent bruises, shrink and injuries. Sudden stops and acceleration that is too rapid increases injuries and stress. To comply with environmental regulations, truck floors should be leakproof to prevent urine and manure from dripping onto the highway. With today’s modern taller cattle, it is essential that semi-trailers have sufficient height between decks to prevent back injuries. Overloading of trucks will increase bruising. In one survey, overloading two extra head of cattle increased bruising. Overloading of hog trucks will increase death losses and PSE. To prevent skin blemishes, hog trucks should be cleaned after each load.

When the temperature is over 60 degrees, (14 degrees C) use wet sand or wet shavings to keep hogs cool. If the temperature is over 80 degrees, (27 degrees C) sprinkle hogs with water prior to loading at buying stations or on the farm. Never bed hogs with straw during hot weather. When the temperature is below 60 degrees, bed hogs with straw or deep, dry shavings to keep them warm. In the northern regions, approximately half of the air holes in aluminum trailers transporting hogs should be covered with panels or plastic plugs during the winter. Very cold weather below (10° F)(-24 C) bed hogs deeply with straw to prevent frostbite.

Veal calves can require special care in transport because they are so young. Take care in cooler temperatures (below 60 degrees) to provide straw bedding and plug some airholes in trucks so the calves do not become too cold.

People trucking and handling animals need to understand both wind chill factors and heat stress. Wind chill can kill livestock. Wetting the haircoat on cattle destroys its ability to insulate the animal’s body. Death losses in cattle are often greatest when the temperatures are near freezing and either rain or freezing rain blows into a truck. Dry cold weather is less hazardous to cattle because the coat retains its ability to insulate. Wind chill can make the back of a trailer very cold. When an open truck is moving 50 mph on a 20-degree (-6C) day, the wind chill factor for hogs is minus 23 degrees (-33 C).

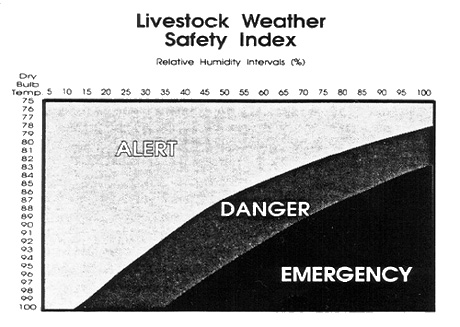

The combination of a high temperature and humidity is especially detrimental for hogs. When the Livestock Weather Safety index is in the Danger and Emergency Zone, try to schedule hog shipments for the early morning.

Heat Stress Chart – The chart provides a guide for plant managers and truckers to help reduce heat stress on livestock. Hazard to the animal increases when both temperature and humidity increase. When conditions are in the alert zone, truckers need to be careful to keep hogs cool. When conditions get into the danger and emergency zone, try to schedule as many hog shipments as possible in the early morning or at night. (From Livestock Conservation Institute Livestock Trucking Guide – now National Institute of Animal Agriculture).

If this is not possible, trucks should be kept moving and drivers should not be allowed to stop at the coffee shop with a loaded trailer. When the truckers reach the plant, they must be unloaded promptly. Heat and humidity become extremely critical at 80°F at 80% humidity.

| Feedlot Fed Steers or Cows, Avg. Wt. |

Horned or Tipped or more than 10% Horned and Tipped |

No Horns (polled) |

|---|---|---|

| 800 lbs. (360 kg) | 10.90 sq. ft. (1.01 sq m) | 10.40 sq. ft. (0.97 sq m) |

| 1000 lbs. (454 kg) | 12.80 sq. ft. (1.20 sq m) | 12.00 sq. ft. (1.11 sq m) |

| 1200 lbs. (545 kg) | 15.30 sq. ft. (1.42 sq m) | 14.50 sq. ft. (1.35 sq m) |

| 1400 lbs. (635 kg) | 19.00 sq. ft. (1.76 sq m) | 18.00 sq. ft. (1.67 sq m) |

| Market Weight Hogs | Winter | Summer (Temp. Is 75° ) |

| 200 lbs. (90 kg) | 3.50 sq. ft. (0.32 sq m) | 4.0 sq. ft. (0.37 sq m) |

| 250 lbs. (113 kg) | 4.26 sq. ft. (0.40 sq m) | 5.00 sq. ft. (0.46 sq m) |

| Slaughter Weight | Lambs and Sheep Shorn | Full Fleece |

| 60 lbs. (27 kg) | 2.13 sq. ft. (0.20 sq m) | 2.24 sq. ft. (0.21 sq m) |

| 80 lbs.(36 kg) | 2.50 sq. ft. (0.23 sq m) | 2.60 sq. ft. (0.24 sq m) |

| 100 lbs. (45 kg) | 2.80 sq. ft. (0.26 sq m) | 2.95 sq. ft. (0.27 sq m) |

| 120 lbs. (54 kg) | 3.20 sq. ft. (0.30 sq m) | 3.36 sq. ft. (0.31 sq m) |

Livestock may become agitated or balk at strange sounds or the smell of the rendering plant. They are reacting to the strangeness of the smell. They do not know what it is, because they have never smelled these smells before.

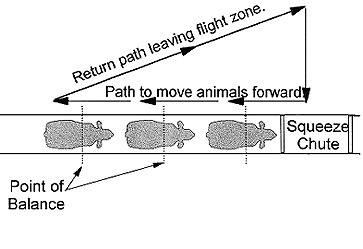

Understanding Flight Zone and Point of Balance – Handlers who understand the concepts of flight zone and point of balance will be able to move animals more easily. The flight zone is the animal’s personal space and the size of the flight zone is determined by the wildness or tameness of the animal. Completely tame animals have no flight zone and people can touch them. An animal will begin to move away when the handler penetrates the edge of the flight zone. If all the animals are facing the handler, the handler is outside the flight zone.

|

|

Flight Zone Diagram – This diagram shows the correct positions for the handler to move livestock. To make an animal go forward, he should work on the edge of the flight zone in positions A and B. The handler should stand behind the point of balance to make an animal go forward and in front of the point of balance at the shoulder to make an animal back up.

To keep animals calm and move them easily, the handler should work on the edge of the flight zone. He penetrates the flight zone to make the animals move and he backs up if he wants them to stop moving. The best positions are shown on the diagram. The handler should avoid the blind spot behind the animal’s rear. Deep penetration of the flight zone should be avoided. Animals become upset when a person is inside their personal space and they are unable to move away. If cattle turn back and run past the handler while they are being driven down a drive alley in the stockyard, overly deep penetration of the flight zone is a likely cause. The animals turn back in an attempt to get away from the handler. If the animals start to turn back, the handler should back up and increase distance between himself and the animals. Backing up must be done at the first indication of a turn back. If a group of animals balk at a smell or a shadow up ahead, be patient and wait for the leader to cross the shadow. The rest of the animals will follow. If cattle rear up in the single file chute, back away from them. Do not touch them or hit them. They are rearing in an attempt to increase the distance between themselves and the handler. They will usually settle down if you leave them alone.

The point of balance is at the animal’s shoulder. All species of livestock will move forward if the handler stands behind the point of balance. They will backup if the handler stands in front of the point of balance. Many handlers make the mistake of standing in front of the point of balance while attempting to make an animal move forward in a chute. Groups of cattle or hogs in a chute will often move forward without prodding when the handler walks past the point of balance in the opposite direction of each animal in the chute. It is not necessary to prod every animal. If the animals are moving through the chute by themselves, leave them alone. Often they can be moved by lightly tapping or loudly banging the side of the chute.

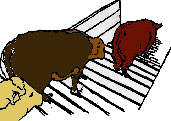

Using Animal’s “Follow the Leader” Instinct – Livestock will follow the leader and handlers need to take advantage of this natural behavior to move animals easily. Animals will move more easily into the single file chute if it is allowed to become partially empty before attempting to fill it. A partially empty chute provides room to take advantage of following behavior. Handlers are often reluctant to do this because they are afraid the line will run out and miss notches on the power chain. Once a handler learns to use this method, he will find that keeping up with the line will be easier. As animals enter the crowd pen, they will head right up the chute.

One of the most common mistakes is overloading the crowd pen which leads to the single file chute. The crowd pen and the staging alley between the crowd pen and the yards should be filled half full. Animals need room to turn.

Cattle move into single file, following the leader.

Handlers must also be careful not to push the crowd gate up too tightly. It often works best to leave the crowd gate on the first notch and to let the animals flow into the single file chute. This will work after all the distractions have been removed from a facility. The crowd pen should become the “passing through” pen. The crowd gate may be used to follow the animals and should never be used to forcibly push them. The handler should concentrate on moving the leaders into the chute instead of pushing animals at the rear of the group.

One-way or sliding gates at the entrance to the single file chute must be open when livestock are brought into the crowd pen. Cattle will balk at a closed gate.

Holding a one-way gate open to facilitate cattle entry into the chute.

One-way flapper gates can be equipped with a rope to open them by remote control from the crowd pen. When the crowd pen is operated correctly, electric prods can usually be eliminated and non electric driving aids such as flags, rattle paddle and sticks with streamers can be used. Animals can easily be turned with these aids. To turn an animal, block the vision on one side of its head with the streamers. If the leader balks at the chute entrance, a single poke with the prod may be required. Once the leader enters, the rest of the animals will follow.

Dealing with Excitable Hogs – There have been problems with highly excitable hogs which are difficult to drive at the packing plant. These animals squeal, bunch and pile up. It is difficult to make these hogs separate and walk up the chute. They will constantly balk. It is caused by a combination of genetic selection for rapid weight gain and a lack of stimulation in confinement buildings.

Packers and producers need to work together to produce hogs which will have both rapid weight gain and good meat quality. Highly excitable hogs have severe PSE due to agitation during handling. PSE levels will be high even though these hogs are negative on the halothane test for PSS (Porcine Stress Syndrome). Quiet, calm handling is almost impossible due to their bad temperament.

Excitability problems can be reduced and hogs will be easier to drive if people walk through the finishing pens at least once a week. The person should walk quietly in a different random direction each time to train the hogs to quietly get up and flow around them. Playing a radio on the finishing barn gets the animals accustomed to different kinds of sounds. Bad flooring in the finishing bar can also cause problems. Hogs finished on metal or plastic floors will have excessive hoof growth. These animals will balk constantly in the plant.

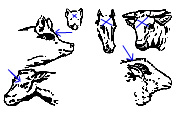

Captive Bolt Stunning – To produce instantaneous unconsciousness, the bolt must penetrate the brain with a high concussive impact. The correct positions for stunner placement are shown in the diagram. For cattle, the stunner is placed on the middle fo the forehead on an “X” formed between the eyes and the base of the horns.

Proper captive bolt stunner placement positions.

Captive bolt stunner placed on the head of a steer in the correct position.

For sheep, a captive bolt is place don the top of the head. This position is more effective for sheep because they have a very thick skull over the forehead. For hogs, the captive bolt is placed on the forehead.

A good stunner operator leans not to chase the animal’s head. Take the time and aim for one good shot. The stunner must be placed squarely on the animal’s head. All equipment manufacturers’ recommendations and instructions must be followed. Pneumatic stunners must have an adequate air supply. Low air pressure is one cause of poor stunning. Heavy pneumatic stunners should be equipped with ergonomic handler to aid positioning.

Poor maintenance of captive bolt stunners is a major cause of bad stunning. Stunners must be cleaned and maintained per the manufacturers instructions. Good maintenance requires a person who has dedicated time each day to maintain stunners. A verified maintenance program where a mechanic signs off each day that he/she has tested the stunners is recommended. If a test stand is available for your brand of stunner, it should be used daily to test bolt velocity. It is important to keep stunner cartridges dry and the correct cartridge strength must be used. Store cartridges in a room with low humidity such as an office. Damp cartridges which have not been stored properly will cause poor stunning.

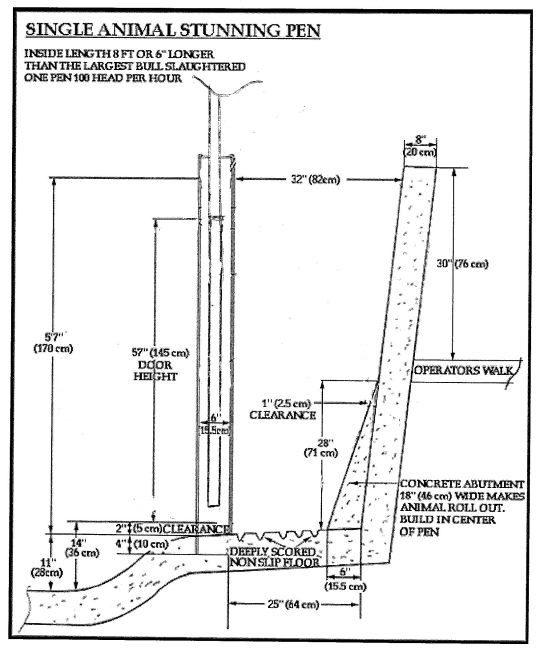

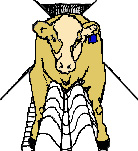

Proper Cattle Restraint for Stunning – If a stunning box is used. It should be narrow enough to prevent the animal from turning around. The floor should be non-slip so the animal can stand without losing its footing. It is much easier to stun an animal that is standing quietly. Only one animal should be placed in each stunning box compartment to prevent animals from trampling on each other.

Well-designed cattle stunning box.

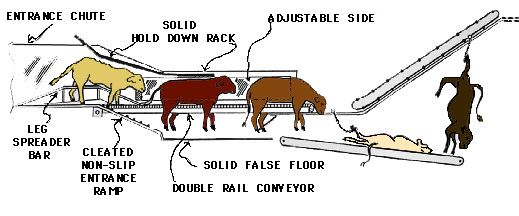

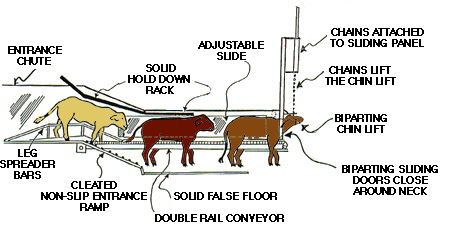

Most large plants restrain cattle and hogs in a conveyor restrainer system. There are two types of conveyor restraints, the V restrainer and the center track system which is used in many beef plants. In a V restrainer system, the cattle or hogs are held between two angled conveyors. In the center track system the cattle ride astride a moving conveyor. The center track system provides the advantages of easier cattle stunning and improved ergonomics because the stunner operator can stand closer to the animal. Either type of restrainer system is much safer for workers than cattle in a stunning box. Restrainer conveyors are recommended for all plants which slaughter over 100 head per hour. Stunning boxes are difficult and dangerous to operate at higher speeds. In a plant which slaughtered 160 cattle per hour, replacement of multiple stunning boxes with a conveyor restrainer eliminated at least one serious accident each year.

|

|

|

|

|

|

Lighting in the restrainer room over the top of the conveyor will help induce animals to raise their heads for the stunner. Animals should not be able to see light coming up form under the restrainer because it may cause balking at the entrance. Restrainer systems should be equipped with a long, solid hold-down rack to prevent rearing. The hold-down should be long enough so that the animal is fully settled down onto the conveyor before it emerges from under it. This hold down should not press on the animal’s back. It is a visual barrier.

If an animal is walking into the restrainer by itself, do not poke it with an electric prod. Center rack systems require less prodding to induce cattle to enter it. Workers need to break the “automatic prod reflex” habit.

CAUSES:

If an animal is walking into the restrainer by itself, do not poke it with an electric prod. Center rack systems require less prodding to induce cattle to enter it. Workers need to break the “automatic prod reflex” habit.

Trouble Shooting Problems in Center Track Conveyor Restrainer Systems and V Belt Restrainer Systems for Cattle, Pigs and Sheep

PROBLEM: Animals struggle in the restrainer

Causes:

Electric Stunning of Hogs and Sheep – To produce instantaneous, painless unconsciousness, sufficient amperage (current) must pass through the animal’s brain to induce an epileptic seizure. Insufficient amperage or a current path that fails to go through the brain will be painful for the animal. It will feel a large electric shock or heart attack symptoms, even though it may be paralyzed and unable to move. When electric stunning is done correctly, the animal will feel nothing.

There are two types of electric stunning, head only and cardiac arrest stunning which stops the heart. Most large plants use cardiac arrest head to back or head to side of body stunning. It produces a still carcass that is safer and easier to bleed. Cardiac arrest stunning requires the use of a restraining device to prevent the anima from falling away from the stunning wand before it receives the complete stun. Cardiac arrest stunning kills the animal by electrocution. Head only stunning is reversible. Hogs and sheep which are stunned with a head only stunner must be bled within a maximum interval of 30 seconds to prevent them from regaining consciousness. An interval of 10 to 17 seconds is recommended

Electric head-to-back stunner placed in the correct position on a hog in V restrainer.

When cardiac arrest stunning is used, one electrode must be placed on either the forehead or in the hollow behind the ears and the other electrode is placed on either the back or the side of the body. The head electrode should not be allowed to slide back onto the neck or onto the hog’s jowls. When head only stunning is used, the electrodes may be either placed on the forehead or clamped over around the sides of the head like ear muffs. Hogs should be wetted prior to stunning. The stunning wand must be applied to the animal for two to three seconds to stun properly. Stunners should be equipped with a timer.

Meat packers should use amperage, voltage and frequency settings which will reliably induce unconsciousness. Both properly and improperly stunned cardiac arrested animals can look similar (Gilbert and Devine, 1991). Current flow through the spine masks the epileptic seizure. If there is any question, electrical parameters should be verified by scientifically valid measurements (See Good Management Practices for Animal Handling and Stunning).

To prevent bloodspots in the meat and pain to the animal, the wand must be pressed against the animal before the button is pushed. The operator must be careful not to break and make the circuit during the stun. This causes the animal’s muscles to tense up more than once and bloodspots may increase. Stunning wands and wiring should be checked often for electrical continuity. A worn switch may break the circuit enough to cause bloodspots. Electrodes must be kept clean to provide a good electrical contact. Operators must never double stun animals or use the stunning wand as a prod.

Modern stunning circuits use a constant amperage design. The amperage is set and the voltage varies with hog or sheep resistance. Older style circuits are voltage regulated. These circuits are inferior because they allow large amperage surges which can fracture bones and cause bloodsplash. The distance between the head electrode and the back electrode should not exceed 14 inches. The most modern sheep stunners from New Zealand utilize water jets to conduct electricity down through the wool.

Preventing Bloodsplash (Bloodspots) – Handle animals gently. Gentle handling prevents damage to small blood vessels caused by excited animals jamming against each other or equipment. Electric prod usage should be kept at a minimum. Animals should never be left in the restrainer system during breaks and lunch. Bloodsplash may also be increased if one side of a V restrainer runs faster than the other. This causes stretching of the skin which damages blood vessels. Both sheep and hogs should be bled within 15 seconds after stunning to minimize meat damage. The slats on the V restrainer and hold-down rack should be insulated to prevent current leakage which can cause bloodsplash.

Rapid temperature fluctuations and periods of extremely hot weather can greatly increase the incidence of bloodsplash. In these circumstances, plants should take extra care in handling animals to minimize bloodsplash problems.

The gas mixture and the time that pigs remain immersed in the gas must be adjusted so that unconsciousness is induced calmly and the pigs remain insensible throughout shackling, bleeding and slaughter. Handlers must be careful not to overload the gondolas (elevator boxes) that hold groups of pigs. In a properly loaded gondola, the pigs must have sufficient room to stand or lie down without being on top of each other. Handlers must never overload the gondolas by forcing pigs to jump on top of each other.

Below are the signs of a properly stunned animal:

These methods can be used for determining insensibility for all types of stunning and for ritual slaughter which is done without stunning. Just remember, kicking reflexes are normal in captive bolt-stunned animals, electrically stunned animals and after ritual slaughter. They should be absent for CO2. Captive bolt stunning induces instant insensibility by both concussion and physical destruction of the brain. Stunner maintenance is essential to maintain maximum hitting power.

Electric stunning renders an animal instantly insensible by inducing a grand mall epileptic seizure. Scientific research has shown that in order to induce the seizure, the electric stunner must be set at a minimum of 1.25 amps for market weight pigs and 1 amp for sheep. Large sows will require 2 or more amps. If lower amperages are used the stunner may induce cardiac arrest but the animal will feel the shock because the seizure was not induced. Electrical frequencies up to 800 hz (cycles) can be used.

Frequencies over 800 hz should not be used. Research has shown that 1500 cycles failed to induce instant insensibility. Animals that are dehydrated may have high electrical resistance and be difficult to stun. If an electrically stunned animal blinks within 5 seconds after stunning, there is a sign that the amperage is too low. In electrically stunned animals, blinking should be checked within 5 seconds and after 60 seconds. In most plants, blinking will not be found immediately after stunning because the plant is using the correct amperage. After it has been verified that the amperage is set correctly, the most important point to observe for signs of return to sensibility is 60 seconds after electrical stunning. This provides time for the eyes to relax after the epileptic seizure. Checking for signs of return to sensibility after bleeding insures that the animal will not recover.

When stunned animals are viewed from a distance, the most important signs to look for in a properly stunned animal are:

Order of the events which indicate Return to Sensibility in head only electrically stunned pigs:

Causes:

Problem: The initial stun appears to be done correctly but the animal blinks or shows other signs of return to sensibility 30 to 90 seconds after stunning.

Causes:

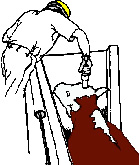

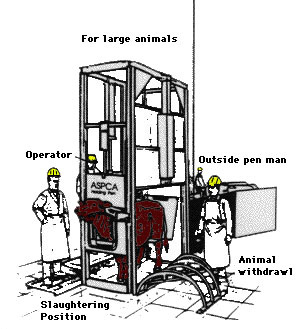

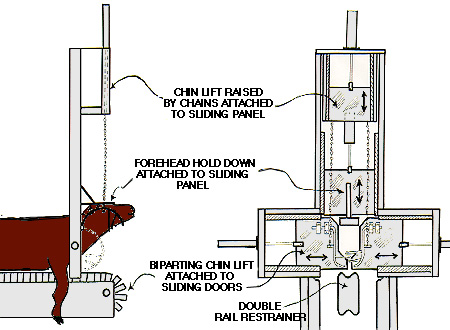

ASPCA Pen – This device consists of a narrow stall with an opening in the front for the animal’s head. After the animal enters the box, it is nudged forward with a pusher gate and a belly lift comes up under the brisket. The head is restrained by a chin lift for the rabbi to perform shehita. Vertical travel of the belly lift should be restricted to 28 inches so that it does not lift the animal off the floor. The rear pusher gate should be equipped with either a separate pressure regulator or special pilot-operated check valves to allow the operator to control the amount of pressure exerted on the animal. The pen should be operated from the rear toward the front. Restraining of the head is the last step. The operator should avoid sudden jerking of the controls. Many cattle will stand still if the box is slowly closed up around them and less pressure will be required to hold them. Ritual slaughter should be performed immediately after the head is restrained.

ASPCA Pen for Ritual Slaughter.

An ASPCA pen can be easily installed in one weekend with minimum disruption of plant operations. It has a maximum capacity of 100 cattle per hour and it works best at 75 head per hour. A small version of this pen could be easily built for calf plants.

Conveyor Restrainer Systems – Either V restrainer or center track restrainer systems can be used for holding cattle, sheep or calves in an upright position during shehita or hold slaughter. The restrainer is stopped for each animal and a head holder holds the head for the ritual slaughter man. Research in Holland indicates that the center track design provides the advantage of reducing bloodspots in the meat.

Small Restrainer Systems – For small locker plants which ritually slaughter a few calves or sheep per week, an inexpensive rack constructed from pipe can be used to hold the animal in a manner similar to the center track restrainer. Animals must be allowed to bleed out and become completely insensible before any other slaughter procedure is performed.

As a general principle, all disabled animals arriving at packing plants should be dispatched to slaughter as promptly as possible to minimize the animal’s suffering.

Offloading From Trucks – All trucks carrying livestock should be unloaded promptly. Trucks carrying disabled animals should unload ambulatory animals first, then promptly unload the animals unable to walk. Delayed unloading can cause death loses and downer animals due to extreme temperatures and stress.

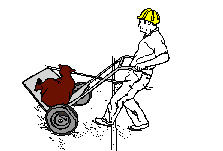

A well-designed cart for moving crippled livestock.

To offload a non-ambulatory animal from a truck, plants should use the truck exit nearest to the animal and should place as little stress as possible on the animal. Animals must never be dropped to the ground from a truck. In some cases, a slide board or cripple cart may be helpful. Animals may be rolled onto a wide piece of conveyor belting that has been stiffened on one end with metal bars to prevent curling when the belting with the animal on it is dragged. The board can then be dragged off the truck and the animal loaded into a suitable mechanical device for transport to an inspection area.

The Humane Slaughter Act prohibits dragging of downed or crippled livestock in the stockyards, crowd pen or stunning chute. By using slideboards and cripple carts, animals can be transported humanely and efficiently to a pen or other area which they can be examined by an inspector, stunned and moved to slaughter.

In all cases, disabled livestock should be handled and moved as little as possible. Trucks carrying downers should park as close to the slaughter area as possible and disabled animals should be inspected by a USDA veterinarian, stunned and moved to slaughter as quickly as possible. Non-ambulatory pigs and sheep are easier to move in a humane manner than a non-ambulatory cow. Many non-ambulatory cattle can be prevented by better management at the dairy or ranch. There are two basic types of non-ambulatory animals. The first type is old breeding stock which have deteriorated to a bad physical state before leaving the farm. This type of non-ambulatory animal is both a food safety and an animal welfare problem. Another type are stressor pigs which become non-ambulatory. Many of these animals can recover. Stressor pigs are a welfare concern but they are not a food safety problem. Quiet, careful handling and genetic selection to remove the stress gene will reduce the incidence of stressor pigs.

Inspection and Slaughtering Considerations – USDA rules require that any “suspect” animal – an animal with signs of abnormalities or diseases – must be held separately and closely examined by a USDA inspection service veterinarian. For meatpackers, this means that downer animals must be held apart from other animals in a “suspect” pen for USDA inspection. “Suspect” animals must be slaughtered separately so inspectors can carefully examine the animal’s carcasses and parts.

Plants should call for the USDA veterinarian as soon as a disabled animal arrives. Once the animal has been examined by the USDA inspector, plants should identify the earliest possible point in production when that animal may be slaughtered “separately.” This separation point should be discussed with the USDA inspector. It should be noted that plants need not always wait until the end of a shift to slaughter a “suspect” animal. Waiting can prolong a disabled animal’s suffering.

If a steer or cow goes down in the single file chute which leads to the stunner, it must be stunned prior to dragging. A cartridge-fired captive bolt on a long handle is recommended. If blood gets on the chute, wash it off to prevent balking. In hog plants, the stunning chute should be equipped with side doors so that stressed-out downer hogs can be easily removed.

Click here to return to the Homepage for more information on animal behavior, welfare, and care.

Click here to return to the Homepage for more information on animal behavior, welfare, and care.